The advent of 3D printing revolutionized manufacturing processes in almost every conceivable industry, and today we engage with 3D printed products in every aspect of our day-to-day living without even realizing it.

But how does the process even work?

Is there just one way of doing it, or multiple methods? What is the difference between their products and their uses?

We’ll answer all these questions and more.

How Does 3D Printing Work?

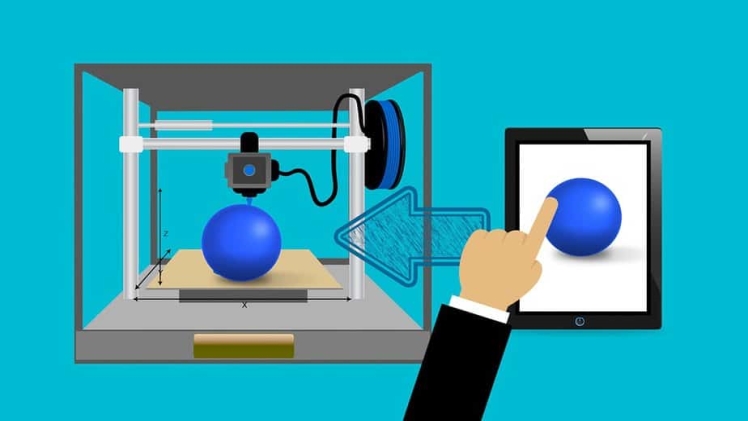

3D printing operates on the same basic principles as a classic inkjet printer: material from a cartridge is impressed on a surface, layer by layer, until a recognizable image emerges. While a classic printer imprints ink onto paper in two dimensions, the 3D printer uses a resin or another polymer to layer the material on itself from the bottom up to create practically any three-dimensional object imaginable.

Both classic and 3D printers use computer software much like the sophisticated program that run the sites where you can claim an online casino welcome bonus. But in this case, the software can envision and instruct the printer on how and when to do the printing.

Are There Different Kinds of 3D Printers?

FDM

Fused Deposition Modelling (FDM) is the most widely used printing method. It employs a continuous extrusion of a thermoplastic filament from a printhead moving along x- and y- axes. Loaded from a spool, the filament is heated and softened in the printhead and hardens immediately when extruded. It’s best used for rapid prototypes and plastic models. The polymer filament is relatively affordable.

Stereolithography

Stereolithography is also used for making fast prototypes. It utilizes a laser to carve more intricate details. Unlike FDM, this method uses a photochemical reaction between the laser in the printhead and the molecules in the filament to create polymers as they are layered in a design. Products of stereolithography are more robust than those of FDM, but the machines and materials are costlier.

DLP

Digital Light Processing is perhaps the oldest method. Like Stereolithography, it uses a photo-chemical reaction to heat filament extruded via a printhead, but DLP uses digital light from chipsets rather than UV light from a laser. The DLP method is faster than stereolithography.

The methods mentioned above are polymer-based 3D printing methods. Below we will talk about metal-based 3D printing methods.

DMSL

Direct Metal Laser Sintering (DMSL) is a popular way for manufacturers to reduce metal use by combining multiple parts in a method like metal casting, except unlike pouring molten metal into a mold, a printhead disperses a later metal powder at the bottom of the cast. It is then struck by a laser (another photochemical reaction) that heats the powder, solidifying it. This process is repeated layer by layer until the device or structure is complete. It creates the most robust and intricate products in materials from titanium to cobalt to steel.

Electron Beam Melting

Much like its name suggests, this method of 3D metal printing involves heating the metal powder with an electron beam produced by heating electromagnetic coils. The cool thing about this method is that the temperature of the electron beam can be altered based on the metal being used.